improve operational excellence and OEE

About

Company

part of a large global groupLocation

BelgiumCompetences

industrial IoT

industry 4.0

capture

monitoring, reporting, alerting

operational insights

OEE improvement

predictive maintenance

data analytics

lifelong learning

industry 4.0 - steel industry

generating operational insights for an improved OEE

relevance

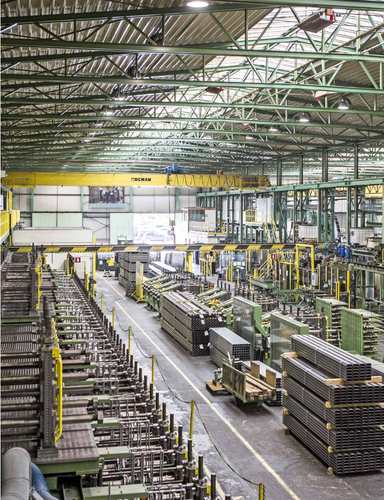

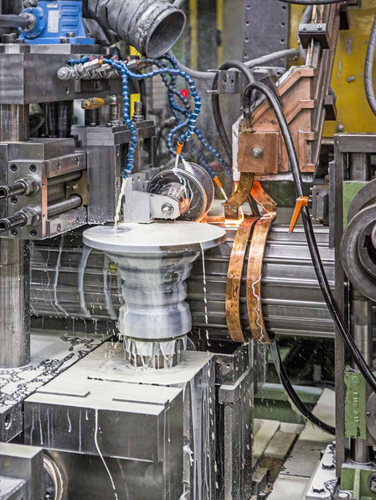

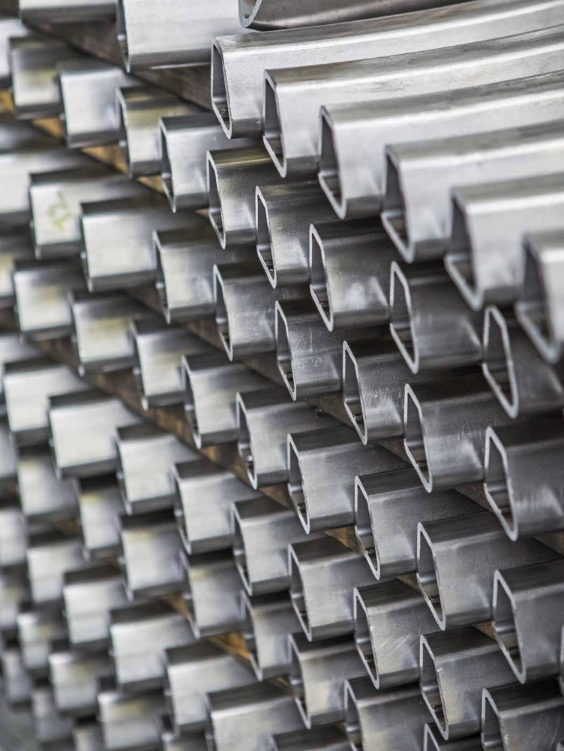

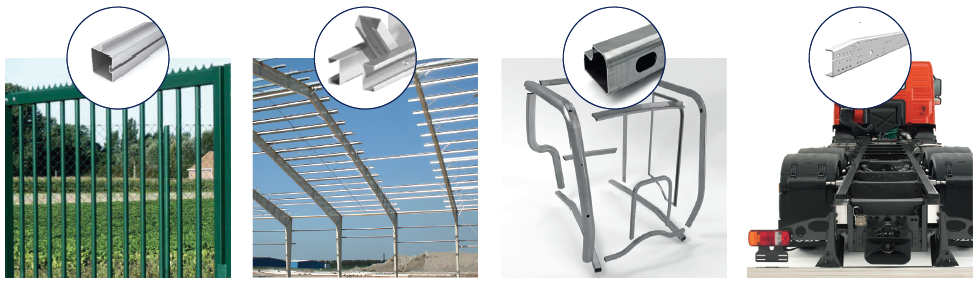

This customer is active in the production of cold-formed steel profiles for a wide portfolio of applications. With their rolled steel profiles, they are a supplier to the construction sector, automotive and truck parts, among others, and they provide custom solutions for various customers.

Precisely because these industries require a high degree of accuracy, this customer wants to deliver more and better products while still reducing operational costs and improving its OEE. In addition, the company wants to prepare for a more sustainable production process in the context of the European Green Deal, which aims for a CO2 neutral Europe by 2050.

In comes capture, vintecc's industrial IoT platform.

challenge

Centralize all available data in real time to gain operational insights in order to improve operational excellence and OEE.

For vintecc the challenges lay in the great variety and different generations of machine controls: new machines and PLC's and retrofitted ones. Although the know-how was present at the customer, the internal capacity - to carry out such a project - was the next challenge.

In addition, the architecture of the system had to end up in the AWS Cloud with the customer's protocols, and everything had to remain manageable and affordable.

Anyone who has ever set up an industrial IoT project knows that this is indeed a challenge.

solution

capture - vintecc's in-house developed industrial IoT platform - is specifically built to solve such issues on such a scale.

It is a powerful data management platform centralizing industrial data and transforming it into time savings and money savings.

capture is a highly customizable, scalable and flexible data framework. Providing operational and actionable insights to every layer of your organization across every stage of your production lifecycle. capture's visual insights help you to reduce time and operational costs, and push your operational performances to the next level.

1proof of concept

- To demonstrate the power of capture and gain the client's trust, vintecc first proposed setting up a PoC (proof-of-concept) in which some valuable cases were identified.

- Thanks to the lightweight and ready-to-use framework, vintecc was immediately able to demonstrate the powerful data logging capabilities. Within 2 hours, vintecc was already collecting and investigating data.

2scale

- After a positive PoC the project scaled to 2 production lines and monitoring 1 other project, the integration was tackled in phases.

- It is precisely because of the flexible and open architecture of the capture platform that vintecc was able to scale immediately in the production environment.

- Additional development costs were therefore no longer necessary, but the implementation of the entire machine fleet had to be planned. Data insights at macro and micro levels now became possible and available.

Data insights

3visualize to get insights

- PLC and sensor data was sent via edge to capture where all data was maintained on premise (at the request of the client).

- capture includes the standard option to visualize the real-time data via a Grafana dashboard so that operators and engineers can detect a potential problem more quickly and take action on it

results

1truck-line

- Reduced scrap & operational costs. Tracing of parts.

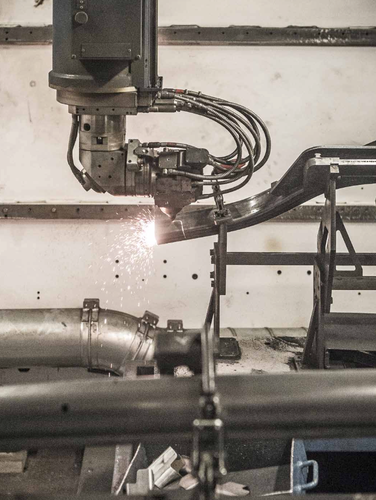

2welding-line

- Debugging of welding programs using high rate data logging. Parameters can be current, tension, alerts, ...

3logging of gates statuses

- To reduce environmental noise, alerts can be generated if the gates are open for too long.